Practical etching rates vary up to 2000 a 2 x 10 4 mm per min.

Ion beam etching ppt.

Dual beam machine 22 05 2015 en seminar 5 fib nano machining machining sputtering milling chemically assisted deposition and etching gas injection system ion beam induced imaging se and si micromanipulation of small objects 2 µm 2 µm 200 nm 2 µm.

The etch tests were performed using the gatan ion beam etching and coating system pecs.

The basic dual ion beam sputtering dibs chamber set up as comprises an etching source that precisely directs a neutralised ion beam onto a wafer located in the substrate holder.

Full surface ion beam etching on 200 mm wafers the scia mill 200 is designed for structuring of complex multilayers of various materials.

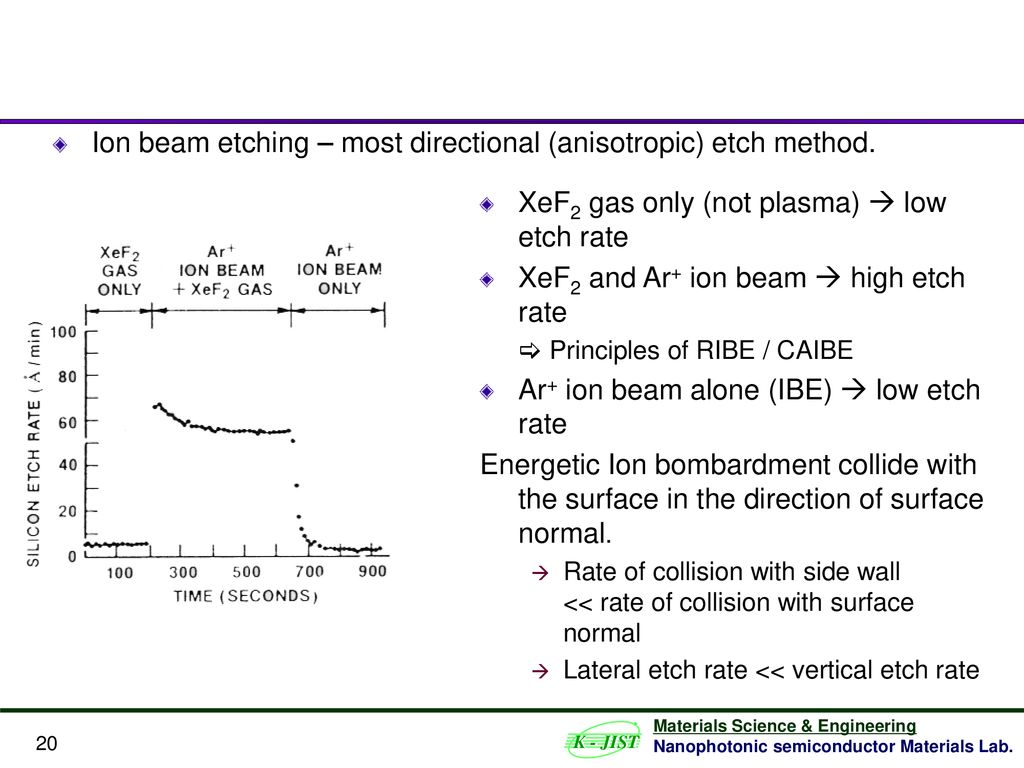

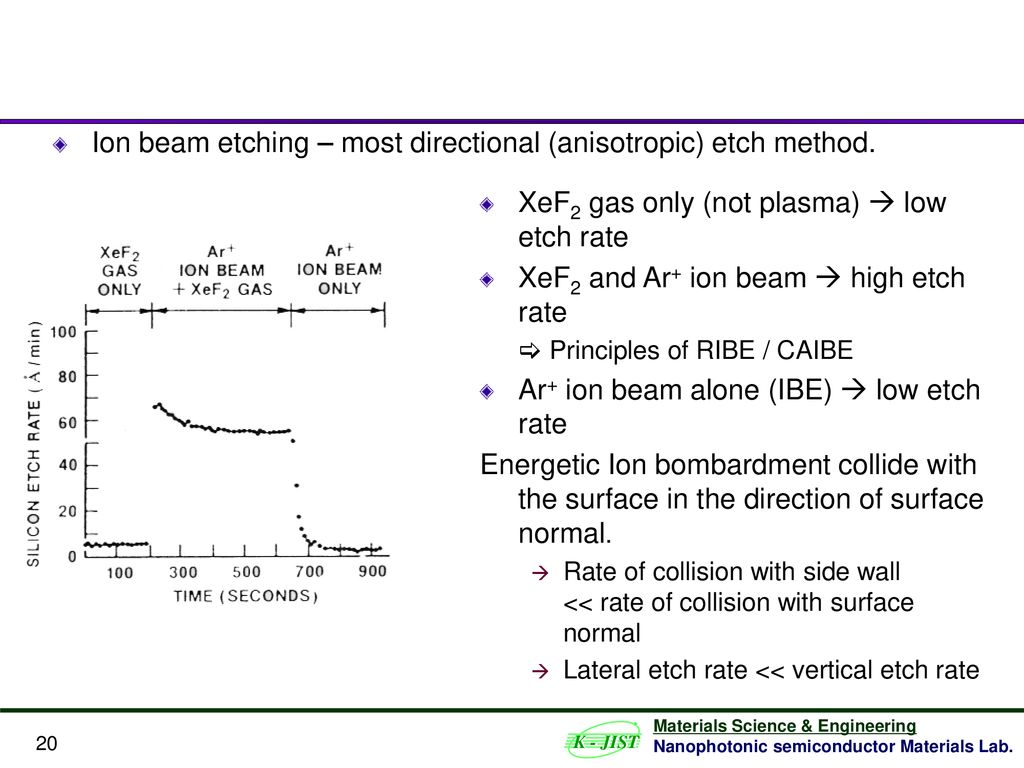

Ion beam etching or milling is achieved by directing a beam of charged particles ions at a substrate with a suitably patterned mask in a high vacuum chamber.

Ion beam etching also known as ion beam milling or ion milling is the most widely used etching method for preparing solid state samples for scanning electron microscopy sem applications in this process the sample material is bombarded with high energy argon ion beams in a high vacuum chamber.

With its fully reactive gas compatibility the system enables reactive etching processes with enhanced selectivity and rate.

Tolerances in the vicinity of 50 å 5 x 10 mm are possible.

Ion beam machining accuracy.

It enables highly directional beams of neutral ions to control over the sidewall profile as well as radial uniformity optimisation and feature shaping during nanopatterning.

With the broad beam ion source in this system etch marks of about 10 mm can be achieved at vertical incidence of the beam dependent on the target material and the parameters.

Normally for good uniformity the 15cm etch source can be used for wafers up to 4 while the 30cm etch source is suitable for wafers up to 8.

Reactive ion etching rie is an etching technology used in microfabrication rie is a type of dry etching which has different characteristics than wet etching rie uses chemically reactive plasma to remove material deposited on wafers the plasma is generated under low pressure by an electromagnetic field high energy ions from the plasma attack the wafer surface and react with it.

The accuracy of the etching process is considerably high mainly due to the small amount of material removal.

Like other dry plasma etch techniques the typical figures of merit apply such as etch rate anisotropy selectivity uniformity aspect ratio and.

Applications of ion beam machining.